Explore our new and EMC stable design, with Air GAP between Touch Sensor and Cover Glass

As a leading display innovations expert, we ensure that the touch displays we develop are reliable and deliver optimal performance under any condition. Our attention to detail enables us to develop flawless designs that meet customer expectations.

From a high-level view, there are two main components that determines the overall touch performance: the touch-sensor design and the touch-controller integrated circuit.

Often, the touch-sensor pattern and layer structure (“stack-up”) are tailored to the touch-controller architecture to maximize SNR.

There are various technical challenges while integrating a projected-capacitive touch sensor into a touchscreen device. A wide range of touch-sensor layer structure exist in the industry today. They are driven by material considerations, device-thickness goals, performance requirements, and cost targets.

Single and multiple substrates, “face-up” and “face-down” structures, variations in the thickness of the X and Y sensor layers, variations in the thickness of optically clear adhesives (OCA), and other factors all affect the signal level produced by the sensor.

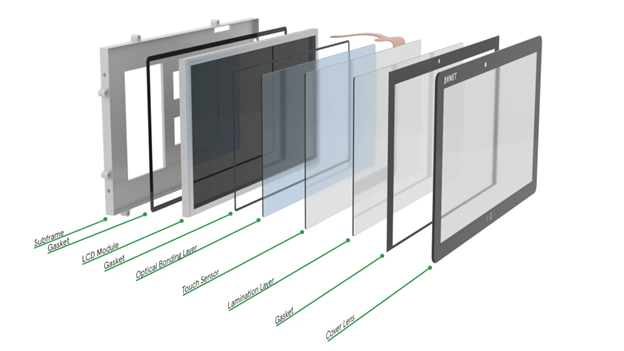

Here an example of a standard stack:

In some applications like white goods electronics or ticketing machines, its best to avoid gluing the cover glass together with the TFT and sensor stack. However, the reasons would be different.

For white good electronics, the reason is that very often companies may have to have different branding for different customers or regions.

And so, it is much easier that the companies add the cover glass by themselves.

So we can provide to our customers always the same stack, base to a TFT and the DITO Sensor with double sided tape on top and the customers can add easily, on their production line, without the use of a clean room, or special bonding/Lamination knowledge.

In case of ticket machines, the issue is that the devices may undergo lot of wear and tear due to continuous and rough operation. Rough usage may cause damage to the coverglass, causing it to break or crack.

If the coverglass is fully glued to the touch sensor and the TFT, and if any damage occurs the company will have to bear the expense of replacing the complete stack. However, with the airgap added in between, in case of any damage, only the coverglass has to be replaced without the need of replacing the entire stack. So replacement becomes cost effective, quick, and easy.

However, when an air gap is introduced between the touch sensor and the cover lens, it becomes more difficult for the touch sensor to detect a finger touch, since the low dielectric-constant of air reduces the signal strength from a finger touch.

One way to solve this problem is to boost the touch system’s sensitivity threshold.

However, this may also attract more noise from the environment, which makes it more difficult for the touch sensor to differentiate a touch from the noise.

For this reason, Avnet Embedded has developed special patterns and parameters for our DITO sensors, so that our solution works now with an air gap on top of the sensor.

The maximum air gap we allow is 0.5mm and ta maximum glass thickness is 7mm. We can do a ruggedized solution that can pass all EMC tests and works also well with gloves and water.