Energy

Power tomorrow’s energy solutions with Tria

Energy OEMs turn to Tria for embedded compute modules, systems, and HMIs for a broad range of energy applications.

Our teams work closely with OEMs to develop secure, reliable and cost-efficient solutions that meet the evolving demands of the global energy sector.

Backed by decades of embedded design expertise, world-class technology partners, European manufacturing facilities, and global logistics, Tria has the scale and experience to support energy OEMs from design to delivery.

Tria supports energy OEMs with:

- Embedded compute modules

- Embedded systems

- HMIs (human machine interfaces)

- Software, OS and BIOS support

Explore our technologies for smarter energy solutions

Tria designs a range of standard compute modules that are ideal for a range of applications in the energy industry. Explore some examples below or view the full range. All modules can be customized or used as starting points for full system designs.

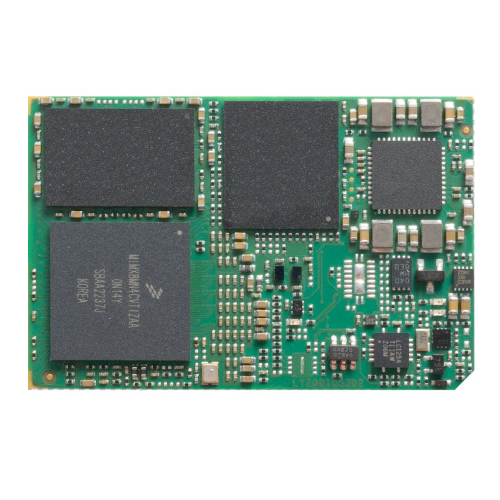

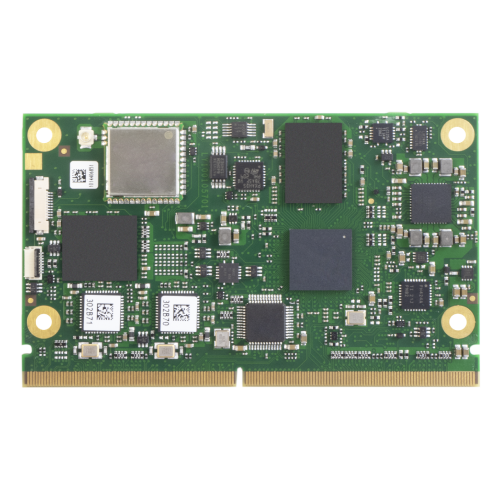

CPU Modules

TRIA OSM-MF-IMX8NANO

- Solo/Dual/Quad core Arm Cortex-A53

- Multimedia 2D/3D GPU (VPU Mini only)

- MIPI-DSI x4, PCI Express Gen. 2 (Mini only)

- 2x USB 2.0, GBE

TRIA OSM-SF-IMX93

- Single / Dual core Arm Cortex-A55 CPU

- MIPI-DSI x4 / LVDS (optional on RGB)

- 2x Gigabit Ethernet (RGMII)

- 2x SPI, 4x I²C, 4x UART, 20 GPIOs, 2x ADC inputs

Explore our standard module ranges

Customization

Tria’s complete Computer-on-Modules act as ready-to-use cores that slot directly into custom board designs, helping energy OEMs reduce development time and accelerate time to market.

We also support custom:

- Carrier boards

- ARM-based single board computers

- BSPs and BIOS

- OS and application software

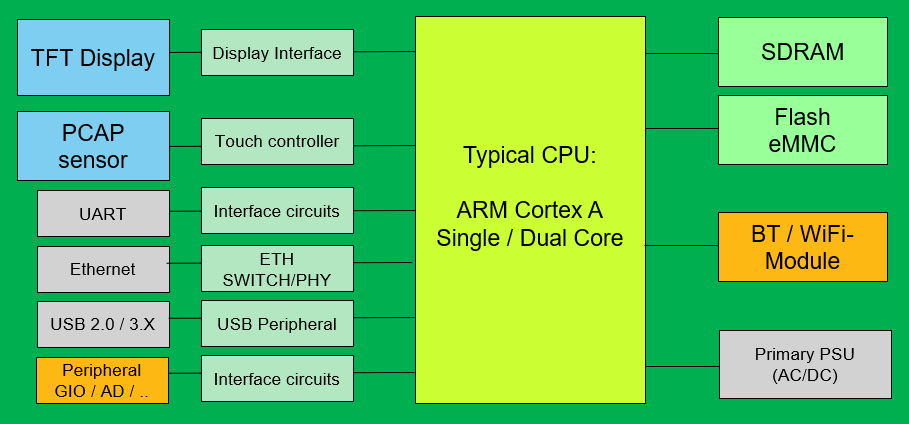

A typical hardware concept for energy solutions

Actual configuration may vary based on customer requirements

Display innovation

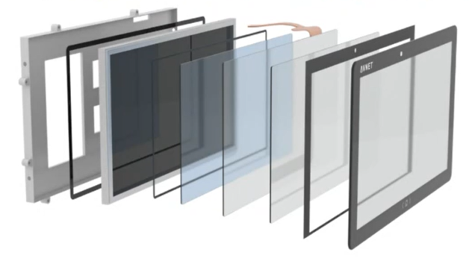

Tria works with all major Tier 1 display manufacturers to deliver custom, application-ready display stacks for energy OEMs. Most projects today require a fully integrated approach that combines display, touch interface, and cover lens in a single bonded solution.

With R&D and engineering based in Germany, and partnerships with key touch, driver, and second-tier display integrators, we support OEMs with tailored solutions for their applications.

For accelerated development without sacrificing quality, standardized platforms like SimpleFlex support faster display integration and time to market.

Typical display and touch specifications

The following specifications reflect typical display and touch requirements for HMIs in energy applications:

Display Size: 5”–7”, depending on UI and function

Display Type: TFT-Display / Ultra Low Power / MIP (Memory in Pixel)

Display Interface: RGB / LVDS

Brightness: Reflective / 350–500 cd/m² (suitable for indoor and outdoor use)

Touch: PCAP low-cost / PCAP button

Bonding: Typical air-gap bonding

Operating Temperature: Extended range of -25°C to +80°C

Longevity: 5+ Years

Display Innovation for Green Energy / Power

Case Study: An HMI for power grid monitoring

A leading energy technology company needed a custom HMI system capable of accurately measuring power grid transients, to support the growing challenges posed by renewable energy integration and vehicle electrification.

Our Approach

Tria designed and manufactured a tailored HMI solution built to enhance network stability and security. The system featured:

- ARM-based custom single-board computer (SBC)

- 6.5” fully custom display touch stack

- Custom plastic housing aligned with customer specifications

The Result

Drawing on decades of expertise in HMI development, CPU integration, and display engineering, Tria delivered a tailored, high-performance solution that exceeded the customer’s expectations.

Our technology partners for energy solutions

We work closely with the world’s leading processor, component, software and specialist technology partners to deliver the best possible solutions for OEMs in the energy industry, including:

Designed and manufactured in Europe, available worldwide.

Empower your energy solutions with Tria

Tria supports energy OEMs with:

- Designing versatile systems for multiple vehicle types and cabins

- Integrating key CPUs, interfaces, and DTC functionality

- Engineering for extreme environments (temperature, shock, vibration, EMC, sunlight)

- Meeting or exceeding industry standards

- Achieving functional safety compliance for critical systems

- Securing reliable supply at SOP with zero disruption risk

- Maintaining stable, long-term product availability with minimal changes

- Delivering product longevity exceeding 10 years

- Extending service and support beyond end-of-production

- Future-proofing solutions to stay at the leading edge for three years or more