Construction & Agricultural Vehicles

The construction, agricultural, and transport vehicle market is evolving rapidly, fueled by advanced IoT, AI, and next-generation communication technologies like 5G and BLE.

This sector presents tremendous opportunities to enhance performance, durability, and efficiency across applications, from helicopter navigation systems to tractor control panels.

However, manufacturers must navigate key challenges, from seamless technology integration and robust connectivity to extreme environmental conditions, stringent safety standards, and operational efficiency.

Those who deliver durable, scalable, and cutting-edge solutions will drive the future of smart mobile plant machinery and next-generation transport systems.

Application - Construction & Agricultural Vehicles

At Tria, we drive transformation in construction, agricultural, and transport vehicles, integrating cutting-edge technology with strict industry compliance.

Our solutions enhance performance and longevity, supporting everything from helicopter navigation systems to tractor control panels.

General Requirements for Construction & Agricultural Vehicles

- Stable, long-term product availability with minimal changes

- Longevity exceeding 10 years

- Reliable supply at SOP with zero risk of disruption

- Extended service support beyond end-of-production

- Versatile design for use across multiple applications and vehicle cabins

- Built for extreme environments (temperature, shock, vibration, EMC, sunlight)

- Future-proofed to remain cutting-edge for at least three years

- State-of-the-art design meeting industry standards

- Support for key CPUs, interfaces, and DTC integration

- Functional safety compliance for critical systems

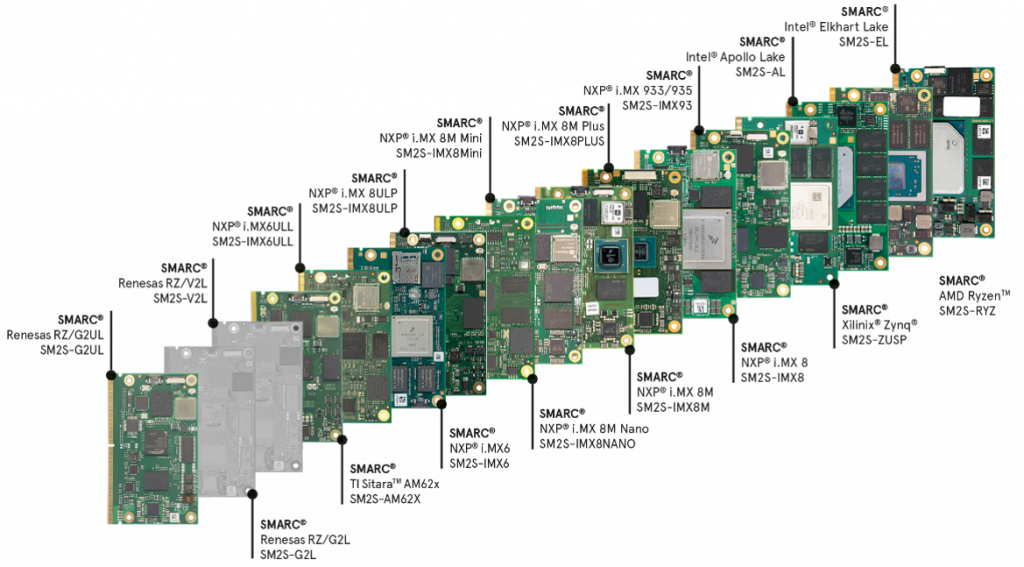

CPU Building Blocks - Construction & Agricultural Vehicles

Typical CPU Platforms for applications at Construction & Agricultural Vehicles

MSC SM2S-EL (Intel Atom® Elkhart Lake)

MSC SM2S-IMX8PLUS (NXP® Cortex® -A53)

MSC SM2S-IMX8PLUS (NXP® Cortex®-A53)

- Triple display support: HDMI, MIPI-DSI, LVDS

- Imaging: 2x MIPI CSI-2 camera

- Connectivity: 2x CAN, USB 3.0, PCIe Gen 3, 2x GbE

- Extended temperature range, in-line ECC, 15-year longevity

MSC SM2S-EL (Intel Atom® Elkhart Lake)

- Triple display support: DP, HDMI, eDP, MIPI, LVDS

- Connectivity: 2x CAN, USB 3.1, PCIe Gen 3, 3x GbE

- Extended temperature range, IBECC, 15-year longevity

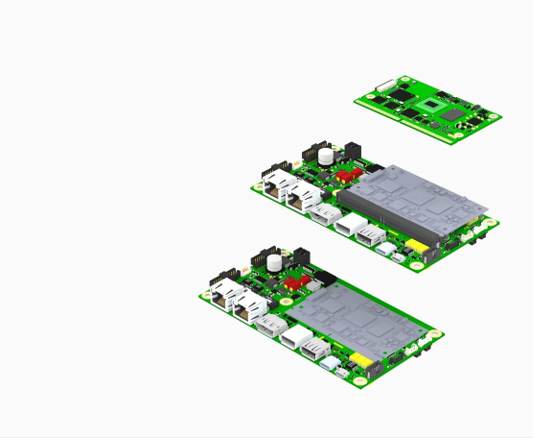

Standard Compute Module

Standard Compute Module on Baseboard / Carrierboard

Compute module technology into full-custom compute design

A complete Computer-on-Module functions as a ready-to-use macro, seamlessly integrating into a full-custom board design for any application.

This significantly reduces development time for customer-specific board designs, accelerating time-to-market with a proven, fully supported solution—including software and firmware.

Custom Board and Software Solutions for Construction & Agricultural Vehicles

- Carrier board

- Custom ARM SBC

- Custom BSP / BIOS

- OS and application software support

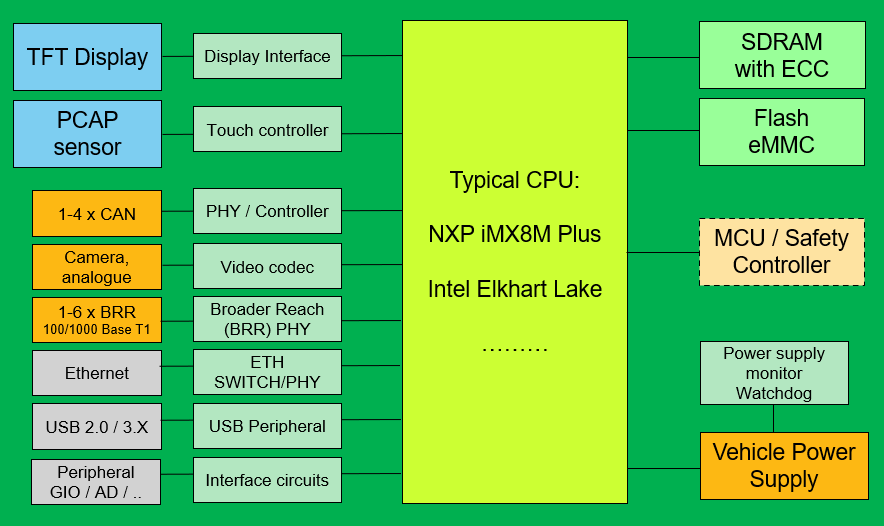

Construction & Agricultural Vehicles - Typical HW Concept

Typical Block Diagram as example for HMI mobile working machines.

(can vary depending on customer requirements)

Experience in typical FuSa functions

- Reliable touch input

- Consistent display output

- Clear and accurate acoustic warnings

- High-integrity camera input

- Storage integrity

- Continuous monitoring of supply voltage, clocks, and software execution

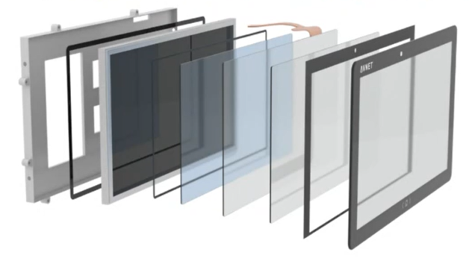

Display Innovation for Construction & Agricultural Vehicles

Tria’s ecosystem includes all major Tier 1 display manufacturers.

Custom displays are the new standard—most AvE projects require a full-stack approach, integrating display, touch, and an application-specific cover lens (glass) in a bonded solution.

With engineering and R&D in Germany and partnerships with leading touch, touch driver providers, and second-tier display integrators, we deliver tailored solutions for your application.

Standardized display touch platforms like SimpleFlex ensure faster time-to-market.

Typical Display – Touch Requirements

Display size: 5”–12.8” (varies by UI, function, and driver cabin)

Brightness:800–1100 cd/m² high-brightness for outdoor use

Touch:PCAP (resistant to 150V/m EMI, water-resistant)

Cover lens:AG / AR / AF coating, IK ≥7 (mechanical impact protection)

UV protection:Shielded against UV exposure

Bonding:Optical bonding (OCR / OCA) for optimal sunlight readability

Operating temperature:-30°C to +85°C (extended temperature range)

Shock & vibration: Engineered for high shock and vibration resistance

Longevity:7+ years (second source for the cell is crucial)

HMI for Roadwork Machines

Customer’s Requirements

To enhance intelligence and efficiency in roadwork machines operating under harsh environmental conditions, the market leader in construction machinery required a fully custom HMI family for its next-generation fleet.

Our Solution

A modular, fully custom HMI system designed for seamless cabin integration and harsh environment qualification, featuring:

- 5”, 7”, and 10.1” TFT displays (1000 cd/m²) with optically bonded PCAP

- ARM-based modular SMARC Computer-on-Module

- 10–15 years of longevity for extended product lifecycle

The Result

With Tria’s modular, ultra-rugged HMI, our customer improved usability, increased efficiency, and reduced costs across its entire product line.

HMI for Agriculture Machines

Customer’s requirements

For its new series of driver cabs, our customer required a rugged HMI with a modern user interface, high brightness, and powerful graphics performance to control vehicle functions and display camera images.

Our Solution

A fully custom HMI system with a separate CPU unit and up to two display units, optimized for seamless cabin integration:

- 12.1” TFT display (1000 cd/m²) with optically bonded PCAP

- x86-based single-board computer

- 10–15 years of longevity for long-term reliability

The Result

By integrating Tria’s modern, touch-based graphical HMI, our customer strengthened its market position while delivering greater efficiency, profitability, and sustainability to the agricultural sector.

Empower your product with Tria

If you’re building the next big thing in construction and agricultural vehicles, Tria can help. Accelerate your product design, save on development costs and take advantage of the latest cutting edge processing by using embedded compute and systems from Tria.

Fill in the form below to reach out, and a member of the Tria team will contact you to discuss your project.