HVAC

The demand for energy-efficient, secure, and intelligent environments is rising, driving manufacturers to adopt advanced IoT solutions.

From heat pumps and smart thermostats to sophisticated air conditioning systems, modern HVAC technologies integrate low-level MPUs, advanced touchscreen displays, high-speed connectivity, AI, and more.

These advancements enhance user experience and drive energy efficiency, but manufacturers face key challenges—transitioning to MPUs, developing custom displays and compute, and ensuring scalability and long-term durability.

Companies that overcome these hurdles and deliver innovative, cost-effective HVAC solutions will lead this fast-evolving market.

Application - HVAC

At Tria, we redefine building security and automation with cutting-edge IoT solutions. From smart thermostats and security cameras to fire safety systems and automated lighting, our technologies turn facilities into efficient, secure, and intelligent environments.

By embedding intelligence into everyday infrastructure, we enhance business value, drive energy efficiency, and accelerate innovation—transforming your vision into reality.

General Requirements for HVAC

- User interface for status and service information (used only a few times per year)

- Cost-competitive solutions

- Long-term reliability (15–20 years in operation post-installation)

- Product longevity (10+ years availability and support)

- Typical production volumes: 50K–300K units per year

- Shift from MCUs to low-level MPUs (IoT connectivity, larger displays, etc.)

- More advanced user interfaces (typical display sizes: 5–7”)

- Front design is critical

- Seamless integration with customer-standard design

CPU Building Blocks - HVAC

Typical CPU Platforms for applications at HVAC

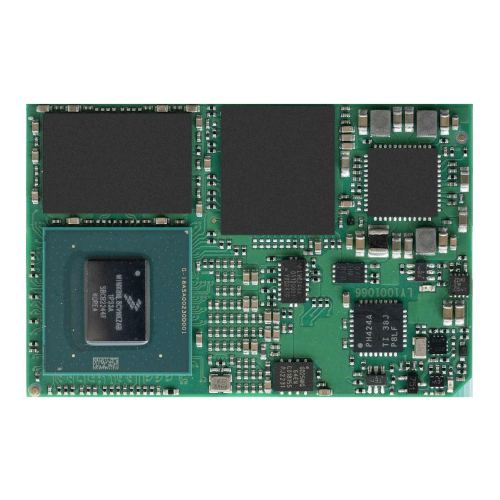

MSC OSM-MF-IMX8PLUS

- Dual/Quad-core Arm Cortex-A53

- Multimedia 2D/3D GPU / NPU (2.3 TOPS)

- MIPI-DSI x4, PCI Express Gen 3

- 1x USB 2.0, 1x USB 3.0, 2x GbE, 2x CAN-FD

MSC OSM-MF-IMX8MINI

- Solo, Dual, or Quad-core Arm Cortex-A53

- Multimedia 2D/3D GPU (VPU available on Mini variant)

- MIPI-DSI x4, PCI Express Gen 2 (Mini only)

- 2x USB 2.0, GbE

MSC C6C-RLP (13th Gen Intel® Core™ CPU)

- Intel® Core™ 13th Gen processor

- Up to 4P+8E cores, 32GB LPDDR5-6400

- IB-ECC, PCIe 8x, TSN/TCC

- Industrial temperature range, industrial UC

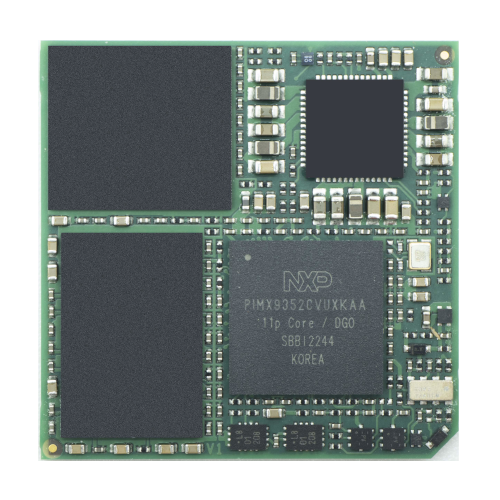

MSC OSM-SF-IMX93

- Single or Dual-core Arm Cortex-A55 CPU

- MIPI-DSI x4 / LVDS (RGB optional)

- 2x Gigabit Ethernet (RGMII)

- 2x SPI, 4x I²C, 4x UART, 20 GPIOs, 2x ADC inputs, 2x CAN-FD

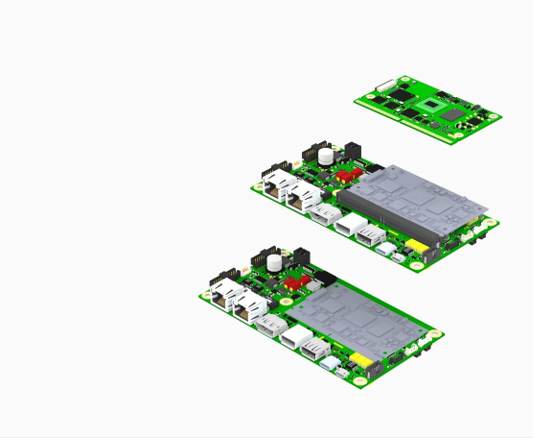

A complete Computer-on-Module functions as a ready-to-use macro, seamlessly integrating into a full-custom board design for any application.

This significantly reduces development time for customer-specific board designs, accelerating time-to-market with a proven, fully supported solution—including software and firmware.

Custom board and software solutions for HVAC

- Carrier board

- Custom ARM SBC

- Custom BSP / BIOS

- OS and application software support

Standard Compute Module

Standard Compute Module on Baseboard / Carrierboard

Compute module technology into full-custom compute design

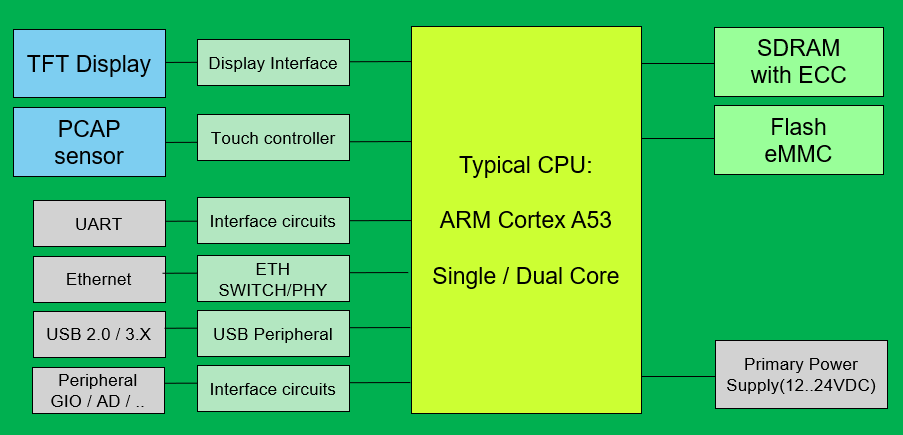

HVAC - Typical HW Concept

Typical Block Diagram “HMI for heat pumps”

Display Innovation for HVAC applications

Tria’s ecosystem includes all major Tier 1 display manufacturers.

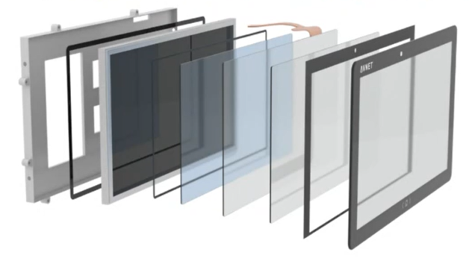

Custom displays are the new standard—most AvE projects require a full-stack approach, integrating display, touch, and an application-specific cover lens (glass) in a bonded solution.

With engineering and R&D in Germany and partnerships with leading touch, touch driver providers, and second-tier display integrators, we deliver tailored solutions for your application.

Standardized display touch platforms like SimpleFlex ensure faster time-to-market.

Typical Display – Touch Requirements

Display size: 5”–7” depending on UI and function

Display type: TFT display / ultra-low power

Brightness: 300–500 cd/m² for indoor use

Touch: PCAP low-cost / PCAP button

Bonding: Typical air-gap bonding

Operating temperature: Extended range of -20°C to +70°C

Longevity: 5–7 years (second source for the cell is crucial)

Custom HMI for Heat Pumps

Customer’s Requirements

- Advance heat pump usability beyond the competition

- Enhance energy efficiency through intelligent control

- Unify the user experience across multiple product series

Our Solution

- ARM-based single-board computer (SBC)

- 5” TFT display with capacitive touch

- Tooling-based plastic housing designed for seamless heat pump integration

- 15-year longevity

The Result

- Lower energy costs for end users through intelligent control

- Increased market share by simplifying usability

- Greater supply chain flexibility in a demanding market through in-house board and system manufacturing

Empower your product with Tria

If you’re building the next big thing in HVAC, Tria can help. Accelerate your product design, save on development costs and take advantage of the latest cutting edge processing by using embedded compute and systems from Tria.

Fill in the form below to reach out, and a member of the Tria team will contact you to discuss your project.