Industrial Automation

The industrial automation market is undergoing a significant transformation, driven by the integration of advanced IoT, AI, and machine learning technologies.

Customers now seek solutions that enhance operational efficiency, reliability, and remote maintenance. Products such as intelligent factory systems and power station controls must perform seamlessly in harsh environments, which can include extreme temperatures and high levels of shock and vibration.

By leveraging high-end computing platforms, robust user interfaces, and customized hardware, manufacturers can address these challenges. Those who deliver innovative, durable, and scalable industrial automation solutions will lead the future of smart manufacturing and operational efficiency.

Application - Industrial / Robotics

Robotics & Cobots are a complex set of technologies which aid us in applications where Humans are unable to work in harsh environments or under extreme time pressures. High performance hardware coupled with stringent reliability means consistent and dependable platforms to enable the future of Robotics. In addition, Factory and industrial automation work seamlessly with Robotics to further accelerate the Factory of the future. Avnet is at the forefront of the industrial revolution with our innovative approach and cutting-edge technologies.

General Requirements for Industrial / Robotics

- Industrial automation robotics

- Long life and legacy support

- Safety Requirements (Machinery Directive 2006/42/EC)

- Remote maintenance (OTA)

- Modular extensions (Extensive IO and connectivity requirements)

- Support for third party hardware and software

- Typical high demand of CPU power

- Harsh Environment (EMI, Temp. / Shock / Vibration)

CPU Building Blocks - Industrial

Typical CPU Platforms for applications at Industrial and robotics

MSC C6C-RLP (13th Gen Intel® Core™ CPU)

- Intel® Core™ 13th gen Processor

- Up to 4C+8C, 32GB LPDDR5-6400

- IB-ECC, PCIe 8x, TSN/TCC

- I-Temp, industrial UC

MSC C6B-MLH (Intel® Core™ Ultra CPU)

- Intel® Core™ Ultra Processor

- Up to 6C+8C, 64GB DDR5-5600

- PEG x8 Gen 4, PCIe 4×4 Gen 4

- CT, PC/client UC

MSC C6C-RYZ2 (AMD R2000 Processor )

- AMD embedded V1000/R1000

- Up to 4C, max. 32GB DDR4-3200

- PEG x8, PCIe 8x

- I-Temp opt.

MSC C6B-RLP (13th Gen Intel® Core™ CPU)

- Intel® Core™ 13th gen Processor

- Up to 6C+8C, 64GB DDR5-4800

- PEG x8 gen 4, PCIe 8x

- TCC/TSN, IBECC, ET, ind. UC

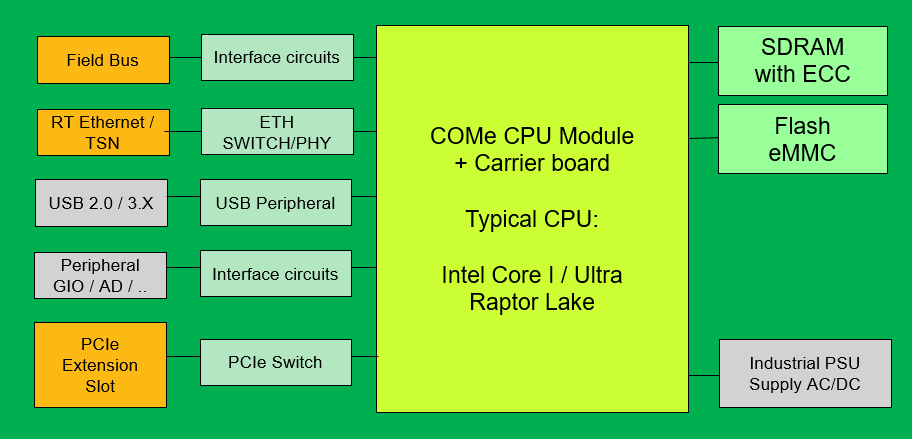

Industrial - Typical HW Concept

Typical Block Diagram “Controller for Industrial / Robotics”

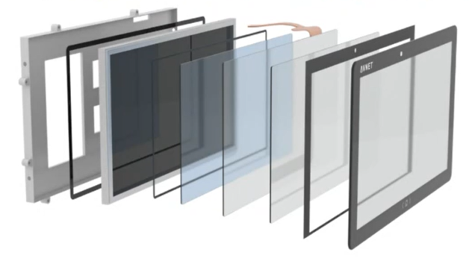

Display Innovation for Industrial / Robotics

Avnet’s Ecosystem consists of all major tier 1 display manufacturers.

Displays go custom – Most AvE projects require Full Stack, i.e. Display, Touch & application specific Cover Lens (Glass) bonded together.

With our engineering / R&D in Germany and cooperation with all major touch & touch driver partners and 2nd tier display integrators we deliver the best solution for your application.

Standardized display touch platforms like SimpleFlex allows fast time to market.

Typical Display – Touch Requirements

Display size: 2,8“ – 15,6“ depending on UI and function

Display type:TFT normally black

Brightness:Brightness of 300 – 500 cd/m² for indoor use

Touch:PCAP (gloves)

Cover lens:AG Coating, IK ≥ 6 (mech. impact)

Bonding:Typical optical bonding

Temp. (op): Standard temperature range of -20 to + 70°C

Longevity:5+ Years

Intelligent Controller for Automation & Drives

Customers’ Requirements

As one of the leading automation and drive technology specialists, our customer needs modular and scalable hard

and software platforms in order to be prepared for future requirements and M2M communication.

Our Solution

Development, certification and delivery of:

- MSC COM Express module with Intel Core i CPU

- Custom carrier / extension boards

- Custom specific extruded plastic housing

The Result

In close collaboration with the customer, Avnet has developed a future-proof and scalable controller solution based on its

own CPU platforms, thereby giving our customer an advantage in its market.

Empower your product with Tria

If you’re building the next big thing in industrial automation, Tria can help. Accelerate your product design, save on development costs and take advantage of the latest cutting edge processing by using embedded compute and systems from Tria.

Fill in the form below to reach out, and a member of the Tria team will contact you to discuss your project.