Medical

Advances in Industry 4.0 and AI are unlocking new opportunities to revolutionize patient care, with telemedicine and remote care management leading the charge. Anti-microbial and chemically resistant coatings, sophisticated thermal management, and fanless, silent operation are redefining medical environments.

At the same time, cutting-edge I/O capabilities are enhancing communication and collaboration across distributed medical teams, while AI-driven diagnostics provide invaluable clinical insights. Yet, with these advancements comes the critical need to safeguard patient data, ensure regulatory compliance, and guarantee 24/7 system reliability over extended lifespans.

Manufacturers that embrace these innovations will be at the forefront of shaping the future of patient care in this rapidly evolving market.

Application - Medical / Healthcare

Tria leads medical and healthcare manufacturing for OEMs, delivering high-precision HMIs, advanced displays, and fully integrated mechanical assemblies for critical ICU equipment and beyond.

With global capabilities, we meet the most demanding medical technology requirements, ensuring stringent certification, long-term reliability, and continuous innovation.

Our expert design teams work in close collaboration with customers, driving cutting-edge advancements in medical technology.

General Requirements for Medical / Healthcare

- Medical processes and certification for design and production (EN 60601 / EN 13485)

- Strict safety and process requirements

- Long product lifecycle with minimal changes (avoiding costly medical re-certification)

- Safe and reliable 24/7 operation with high product reliability

- Rigorous safety and security standards (electrical safety, EMI compliance, software security

- Comprehensive documentation and traceability

- High-performance CPUs, premium display quality, and precise color accuracy

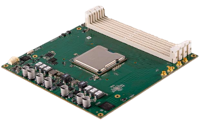

CPU Building Blocks - Medical / Healthcare

Typical CPU Platforms for applications at Medical and Healthcare

MSC HCA-RLP (13th Gen Intel® Core™ CPU)

- COM-HPC Client Module, Size A

- 13th Gen Intel® Core™ Processor

- Up to 14 cores, max. 64GB DDR5-5200

- PEG x8 Gen 5, 16x PCIe Gen ¾

MSC SM2S-SMARC Family

- CPUs: Intel, NXP, Renesas, Qualcomm

- Up to 16GB RAM / 1TB storage

- Multiple connectivity and interface options

- Extended temperature support / 15-year longevity

MSC HSD-ILDL (Intel® Xeon D CPU)

- COM-HPC Server Module, Size D

- Next-gen Intel® Xeon D processor

- Up to 10 cores, max. 256GB RAM

- PCIe x16 Gen 4 + x16 Gen 3, max. 100GbE

MSC C6C-RLP (13th Gen Intel® Core™ CPU)

- Intel® Core™ 13th Gen processor

- Up to 4P+8E cores, 32GB LPDDR5-6400

- IB-ECC, PCIe x8, TSN/TCC

- Industrial temperature range, industrial UC

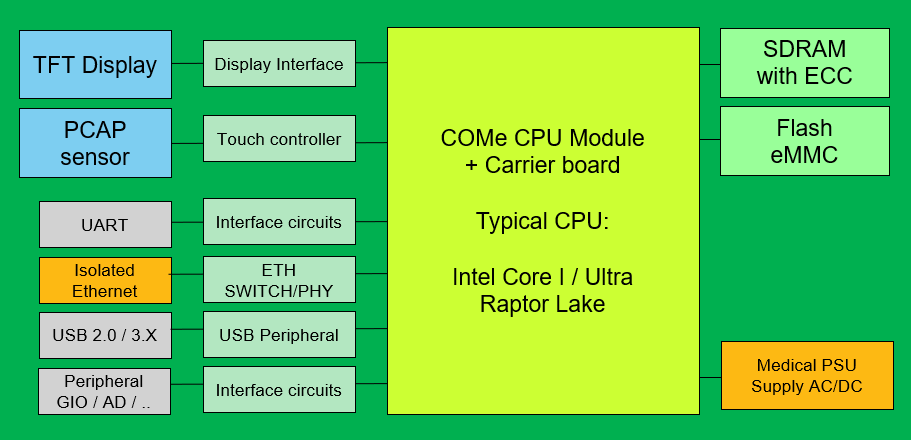

Medical - Typical HW Concept

Typical Block Diagram “HMI for Medical / Healthcare”

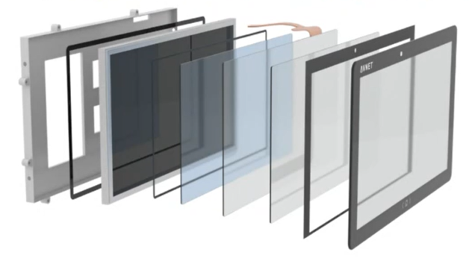

Display Innovation for Medical

Tria’s ecosystem includes all major Tier 1 display manufacturers.

Custom displays are the new standard—most AvE projects require a full-stack approach, integrating display, touch, and an application-specific cover lens (glass) in a bonded solution.

With engineering and R&D in Germany and partnerships with leading touch, touch driver providers, and second-tier display integrators, we deliver tailored solutions for your application.

Standardized display touch platforms like SimpleFlex ensure faster time-to-market.

Typical Display – Touch Requirements

Display size: 12“ – 24“ depending on UI and function

Display type:TFT, Mini LED, High Contrast / Colour Gamut)

Brightness:Brightness of 450 – 1000 cd/m² for indoor use

Touch:PCAP (gloves / pen), 28 V/m, conductive liquids)

Cover lens:AG / AR / AF Coating

Bonding:Typical optical bonding (OCR / OCA)

Temp. (op): Standard temperature range of 0 to + 60°C

Longevity:7+ Years

HMI for Medical

Customer’s Requirements

Intensive care ventilation is a critical function in ICU settings. As a pioneer in medical ventilation, our customer required a remote monitor solution for safe, intuitive operation, ensuring continuous improvements in quality and efficiency for intensive care therapy.

Our Solution

Development and production of a remote monitor solution featuring:

- 15.6” / 18.5” display with optically bonded PCAP

- Controller board enabling remote connection via a single Cat5e cable

- Robot-assisted assembly into an aluminium die-cast housing

The Result

Utilizing medically certified development and manufacturing expertise, Tria delivered a high-quality board and system solution for life-critical applications—ensuring reliability, precision, and seamless integration.

Empower your product with Tria

If you’re building the next big thing in medical, Tria can help. Accelerate your product design, save on development costs and take advantage of the latest cutting edge processing by using embedded compute and systems from Tria.

Fill in the form below to reach out, and a member of the Tria team will contact you to discuss your project.